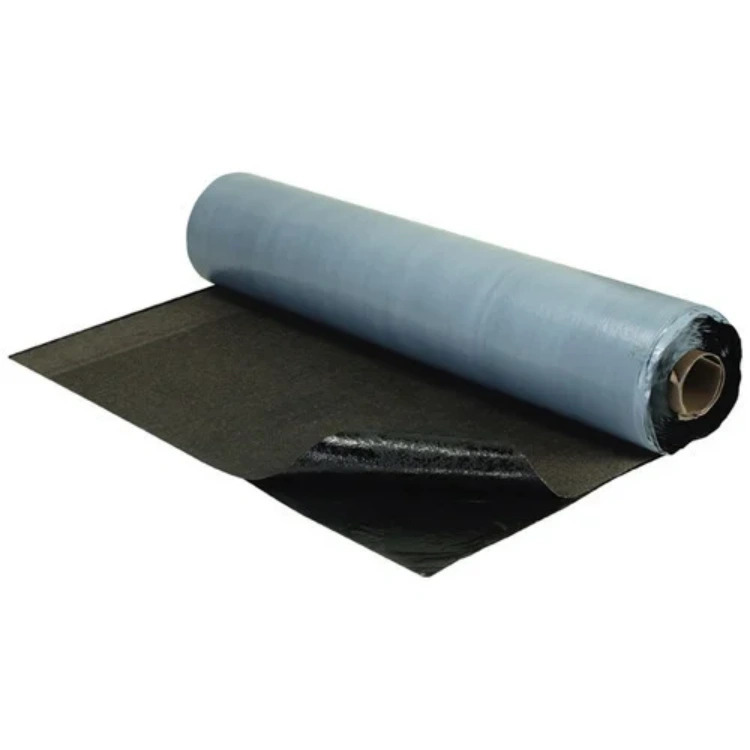

Self-adhesive bituminous waterproofing membrane is widely used because its self-adhesive formulation makes safe, easy and fast installation. We can supply the followings, self-adhesive bituminous Waterproofing membrane with or without reinforcement, one side self-adhesive and double sides self-adhesive.

| Surface | PE film/release film,PET film/release film, Aluminum film/release film, Aluminum foil/PE fim |

| green strong film/release film | |

| Width | 1m |

| Length | 20m/roll 15m/roll 10m/roll 7.5m/roll |

| Standard | GB23441-2009 |

| thick | 1.2mm,1.5mm,2.0mm,3mm,4mm |

| Strengthen material between | non-reinforcement material, glass fiber felt, polyester felt |

1)Safe, easy and fast installation, no naked flame, no binder, no pollution.

2)Excellent adhesive performance, self-healed property.

3)Anti-puncture,anti-tension, good elongation, anti-corrosion.

4)High and low temperature resistance.

5)Widened membranes can reduce loss.

1)Industrial and civil building roofing, underground, pool,tunnel, wooden and metal roofing.

2)Especially in the chemical factory, garment factory, and granary.

3)Tape can be used for sealing all construction material surfaces.

1)Do not apply waterproofing membranes when bad weather, such as raining, snowing, and strong wind.

2)Do not apply on dirty, wet, dusty or humid surfaces.

3)Do not remove the roll from its packaging until the moment of application.

| Tire base material | Top surface material | Product perfomnance | Thickness | width | The measure of area |

| N | PE,PET,D | Ⅰ | 1 .2mm 1.5mm 2.0mm | 1000mm | 10m² 15m² 20m² 30m² |

| Ⅱ | |||||

| PY | PE.S.D | Ⅰ | 2.mm | ||

| Ⅱ | 3.0mm 4.0mm |

| Serial number | Project | index | |||||

| PE | PET | D | |||||

| Ⅰ | Ⅱ | Ⅰ | Ⅱ | ||||

| 1 | Tensile property | Pull(N/50mm)≥ | 150 | 200 | 150 | 200 | – |

| Elongation at maximum tension(%)≥ | 200 | 30 | – | ||||

| Asphalt fracture elongation(%) ≥ | 250 | 150 | 450 | ||||

| Stretch phenomenon | During the tensile process, there is no separation of asphalt coating and film before the fracture of the membrane | – | |||||

| 2 | Nail bar tear strength(N)≥ | 60 | 110 | 30 | 40 | – | |

| 3 | Heat resistance | 70 degrees Celsius, sliding no more than 2mm | |||||

| 4 | Cryogenic flexibility(℃) | -20 | -30 | -20 | -30 | -20 | |

| -20 | |||||||

| 5 | Watertightness(30min) | 0.2Mpa, 120min impermeable | |||||

| 6 | Peel strength(N/mm)≥ | Coil and coil | 1 | ||||

| Coil and aluminium plate | 1.5 | ||||||

| 7 | Nail rod watertightness | adopt | |||||

| 8 | Oil permeability(sheets)≤ | 2 | |||||

| 9 | Viscous(min)≥ | 20 | |||||

| 10 | Thermal aging | Tension retention rate(%)≥ | 80 | ||||

| Elongation at maximum tension(%)≥ | 200 | 30 | 400 | ||||

| Cryogenic flexibility(℃ ) | -18 | -28 | -18 | -28 | -18 | ||

| No crack | |||||||

| Peel strength, coil and aluminium plate(N/mm)≥ | 1.5 | ||||||

| 11 | Thermal stability | Appearance ≤ | Having no bulge, folds, slide,flow | ||||

| Dimensional change rate(%)≤ | 2 | ||||||

| Serial number | Project | index | |||

| Ⅰ | Ⅱ | ||||

| 1 | Soluble content/(g/m²)≥ | 2.0mm | 1300 | – | |

| 3.0mm | 2100 | ||||

| 4.0mm | 2900 | ||||

| 2 | Tensile property | Pull(N/50mm)≥ | 2.0mm | 350 | – |

| 3.0mm | 450 | 600 | |||

| 4.0mm | 450 | 800 | |||

| Elongation at maximum tension(%)≥ | 30 | 40 | |||

| 3 | Heat resistance | 70 degrees Celsius, no sliding, flowing, dripping | |||

| 4 | Cryogenic flexibility(℃) | -20 | -30 | ||

| No crack | |||||

| 5 | Watertightness | 0.3Mpa, 120min impermeable | |||

| 6 | Peel strength(N/mm)≥ | Coil and coil | 1 | ||

| Coil and aluminium plate | 1.5 | ||||

| 7 | Nail rod watertightness | adopt | |||

| 8 | Oil permeability(sheets)≤ | 2 | |||

| 9 | Viscous(min)≥ | 15 | |||

| 10 | Thermal aging | Dimensional stability(%)≤ | 1.5 | 1 | |

| Elongation at maximum tension(%)≥ | 30 | 40 | |||

| Cryogenic flexibility(℃ ) | -18 | -28 | |||

| No crack | |||||

| Peel strength, coil and aluminium plate(N/mm)≥ | 1.5 | ||||

| 11 | Peel strength of self adhered asphalt(N/mm) ≥ | 1.5 | |||

You may also be interested in these products:SBS/APP Modified Bitumen Waterproofing Membrane,PE/PP Composite Waterproof Membrane,PVC Waterproofing Membrane and EPDM Rubber Waterproofing Membrane.